Thermocouples

Thermocouples

A thermocouple is made of two connected, but dissimilar, metal wires that produce an electronic potential directly related to a change in temperature. These changes in voltage are predictable and repeatable in relationship to the temperature. Thermocouples have a wide range in temperature but aren’t as accurate as RTDs or thermistors.

A thermocouple is a measuring device made by joining materials with different Seebeck coefficients. Two wires from dissimilar metals are joined at one end. The emf is generated when a temperature gradient exists between this wire junction and a reference junction. This measurable change of electric potential is the basis of the thermocouple method. The most common materials used in thermocouples are iron-constantan, copper-constantan, chromel-constantan, and two different platinum alloys. Table 1 shows various thermocouple types and materials.

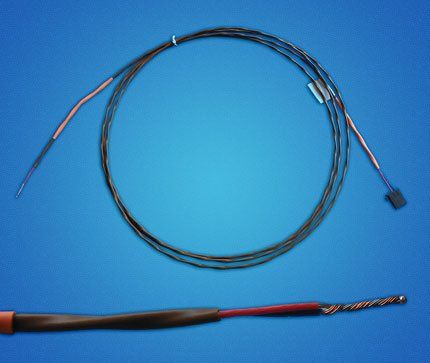

Sensor Scientific makes thermocouples with welded joint that makes the end sensing point durable and it can be used in higher temperature applications than soldered thermocouples. We will make thermocouples to your custom specifications.

Various Thermocouple Styles & Materials

| Type ANSI Symbol | Materials | Temp. Range (°C) | Error +/- (°C) | Application Notes |

| T | Copper-Constantan | 0-350 | 1.0 | When moisture is present. |

| J | Iron-Constantan | 0-750 | 2.2 | For reducing atmosphere. |

| E | Chromel-Constantan | 0-900 | 1.0 | When corrosion possibility. |

| K | Chromel-Alumel | 0-1250 | 2.2 | For clean oxidizing atmosphere. |

| R | Platimum-13% Rhodium/Platimum | 0-1450 | 1.5 | High resistance to oxidation and corrosion. |

| S | Platimum-10% Rhodium/Platimum | 0-1450 | 1.5 | High resistance to oxidation and corrosion. |

For additional information...

Call 800-524-1610

Send us a Message

Request a Quote

All sensors are available in custom assembly form

Related Reading

25 Jun, 2019

When acquiring Thermistors, RTDs, or Thermocouples, you should contact a professional in the industry who can help you choose the best possible device.

22 Jun, 2019

Simply put, this device is used for measuring temperature. The device's functions are made possible by joining materials that have different Setback coefficients. First, two separate wires (from different materials) are connected at the end. Temperature gradients exist to connect the wire junction and reference junctions: this is where EMF is generated. Measuring the change of electrical potential is the basis for thermocoupling in a nutshell. These devices are created in different ways, but they are most commonly made from platinum alloys, chromel-constantan, and iron-constantan. The junctions for thermocouple comes in different forms as well. There are three basic forms to consider. There is: Exposed- these are designed to have the fastest response time of all the different junctions. They are insulated and seals beyond the junction tips. This prevents penetration of gases or liquids into the inner thermocouple. Grounded- this is used when working with high-pressure gases and liquids. This is important when working with high-pressure applications. These devices are electronically joined, which allows for amazing protection of the sheath. Ungrounded- when corrosive conditions are present, you will want to go with ungrounded junctions. The tips are welded on the physical wire, which helps to insulate from the jacket and sheath. Ungrounded Uncommon: This is created with two thermocouples, which are both insulated from the sheath as well as one another. Regardless of the form, thermocouples can be made as portable or permanent. Different types of thermocouples, each of which have their own unique characteristics, are available for purchase. The different types affect temperature range, durability, vibration, and chemical resistance. You have a choice between Type: J, K, T, E, R, S, and B. The devices are great because of their accuracy and price point. They are very affordable. To find more information about the different types of thermocouples, call a local distributor to get a full break down of how each product functions. When comparing thermocouples to RTDs, there is a few things to consider. This includes: Temperature Range- Both products can achieve different ranges, and so you want the one that best works with your application. Cost- thermocouples are usually cheaper but there is a reason behind the cheaper price. Accuracy- RTDs are argued to me more accurate than thermocouples, and this is especially the case for low temperatures. Stability- an RTD tend to be more stable as well. Durability- Thermocouples are built stronger and are more likely to last over several years Consider your different options when it comes to temperature measurement. Getting the proper devices will ensure your applications works smoothly.

We'll Design, Develop & Manufacture to Your Needs.

LET'S WORK TOGETHER!

6 Kings Bridge RoadFairfield, NJ 07004, USA

© 2024

Sensor Scientific, Inc | All Rights Reserved

If you are looking for Thermistor, Standard Chip thermistors, temperature probes for data loggers, Glass Probe Thermistors,

SB Series SMD Chip Thermistor, rtd probe, pt100 rtd,

pt1000 temperature sensor, rtd temperature probe, ntc thermistor, we are your #1 choice.